Категория

контакт

Hydraulic Submersible Slurry Pumps

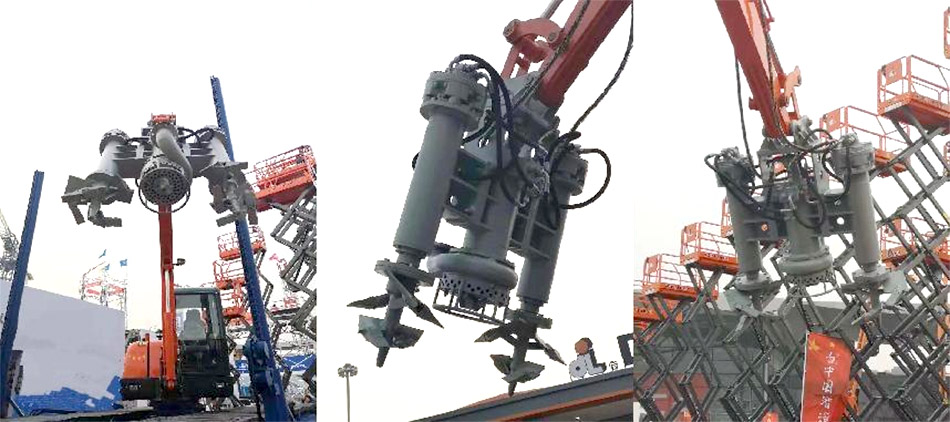

Hydraulic submersible slurry pumps are fundamental devices in different businesses, including mining, development, and wastewater treatment. These pumps are intended to deal with grating and high-thickness slurries, making them ideal for testing conditions.

Flow Rate

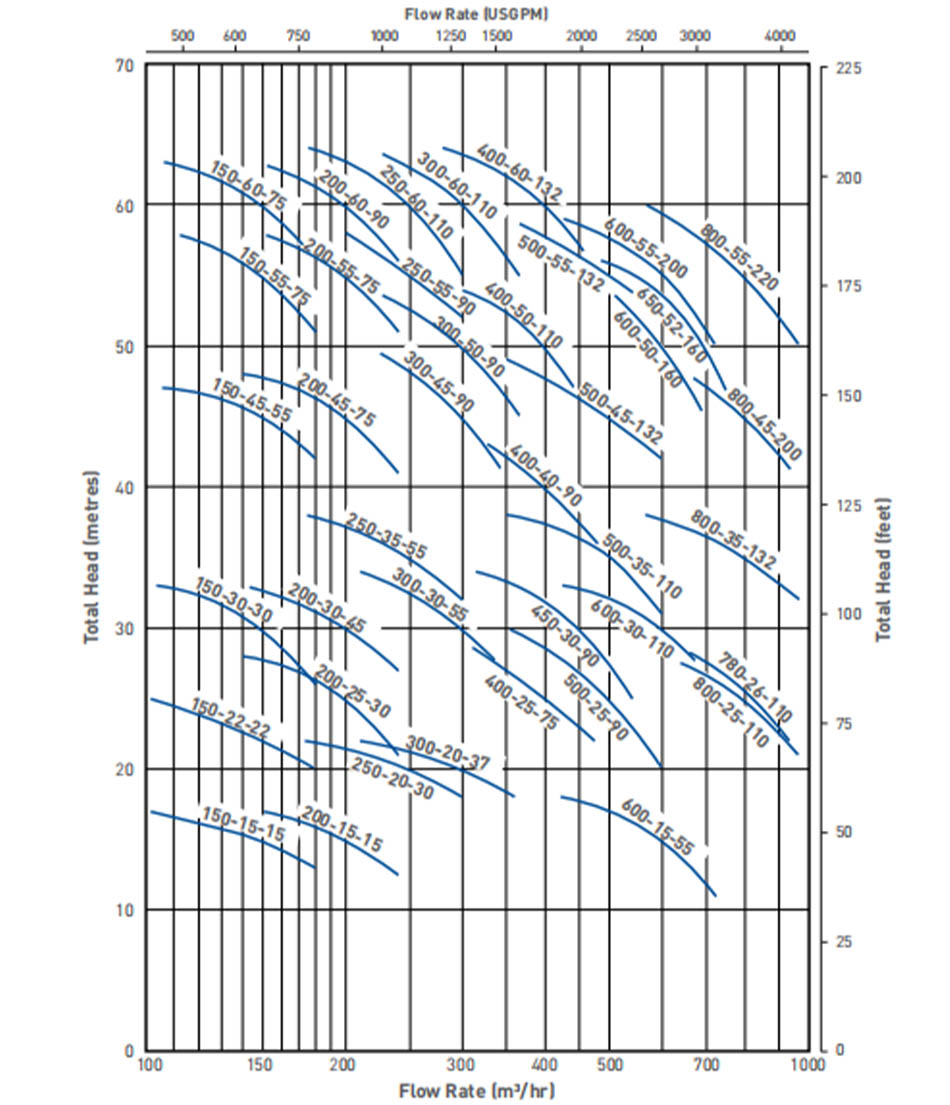

The flow rate of Hydraulic submersible slurry pumps is a critical factor in determining its overall capacity. Modern pumps can achieve impressive flow rates of up to 2000 cubic meters per hour (m³/h). This high flow rate capability makes these pumps suitable for large-scale operations in industries such as mining and dredging, where significant volumes of slurry need to be moved efficiently.

The maximum flow rate of 2000 m³/h is achieved through advanced hydraulic design and and optimization the components of Hydraulic submersible slurry pumps. Manufacturers employ cutting-edge computational fluid dynamics (CFD) simulations to improve the pump's impeller and volute designs, resulting in enhanced flow characteristics and reduced internal losses. Additionally, the use of high-performance materials and precision manufacturing techniques contributes to the pump's ability to maintain high flow rates even when handling abrasive slurries.

It's important to note that the actual flow rate achieved in practice may vary depending on factors such as the specific gravity of the slurry, the concentration of solids, and the system's overall design.

Head: Up To 50 Meters

The head of Hydraulic submersible slurry pumps. refers to the maximum height or pressure to which the pump can lift or push the slurry. With advancements in pump technology, modern pumpumps can achieve heads of up to 50 meters. This impressive head capacity allows these pumps to overcome significant vertical distances and pressure differentials, making them suitable for deep excavation sites, underground mining operations, and high-rise construction projects.

The ability to achieve a head of up to 50 meters is the result of careful engineering and design considerations. Hydraulic submersible slurry pumps manufacturers optimize the impeller geometry, casing design, and overall hydraulic profile to maximize the pump's head capacity while maintaining efficiency. Additionally, the use of high-strength materials in critical components, such as the shaft and bearings, enables the pump to withstand the increased stresses associated with high-head applications.

It's worth noting that the relationship between flow rate and head is inversely proportional. As the head increases, the flow rate typically decreases, and vice versa. Therefore, when selecting Hydraulic submersible slurry pumps, it's essential to consider the specific requirements of the application and choose a pump that can provide the optimal balance between flow rate and head.

Power Rating

The power rating of a pump is a crucial factor in determining its overall performance and capacity. Modern hydraulic submersible slurry pumps offer a wide range of power ratings, typically spanning from 10 kilowatts (kW) to 200 kW. This broad range allows for the selection of pumps suitable for various applications, from small-scale operations to large industrial projects.

The power rating directly influences the pump's ability to handle high flow rates and achieve significant heads. Higher power ratings generally correspond to increased pumping capacity and the ability to handle more challenging slurry compositions. For example, Hydraulic submersible slurry pumps with a power rating of 200 kW would be capable of handling larger volumes of slurry and overcoming greater pressure differentials compared to a pump with a lower power rating.

When selecting a pump, it's important to consider the power requirements of the specific application. Factors such as the desired flow rate, required head, slurry characteristics, and operational duration all play a role in determining the appropriate power rating. Additionally, energy efficiency should be taken into account, as higher power ratings may result in increased operational costs.

Operating Temperature

The operating temperature range of Hydraulic submersible slurry pumps is a critical factor that determines its versatility and suitability for various applications. Modern pumps are designed to operate effectively within a temperature range of -20°C to 120°C. This wide temperature range allows these pumps to be used in diverse environments, from cold climate regions to high-temperature industrial processes.

The ability to operate at temperatures as low as -20°C makes these hydraulic submersible slurry pumps suitable for applications in cold regions, such as mining operations in arctic or subarctic areas. At the lower end of the temperature range, special considerations are given to the pump's materials and lubricants to ensure proper functionality and prevent issues such as freezing or increased viscosity of hydraulic fluids.

On the other end of the spectrum, the ability to handle temperatures up to 120°C allows these pumps to be used in applications involving hot slurries or in environments with elevated ambient temperatures. High-temperature applications may include geothermal power plants, certain chemical processing operations, or industrial processes where heat is generated as a byproduct.

To achieve this wide operating temperature range, Hydraulic submersible slurry pumps manufacturers employ advanced materials and design techniques. High-quality seals, bearings, and hydraulic fluids are selected to withstand extreme temperatures while maintaining their performance characteristics. Additionally, thermal management systems may be incorporated to help regulate the pump's temperature and protect critical components from thermal stress.